When it comes to piston ring manufacturers, the first name that usually comes to mind for most of us is Total Seal [2], and that’s because they’ve been manufacturing piston rings right here in the U.S.A. ever since its founder, Joe Moriarty, invented the gapless piston ring. And at this year’s PRI Show, we had the opportunity to sit down with Keith Jones in the technical department for Total Seal, and discuss what’s new for the company in the upcoming 2017 year.

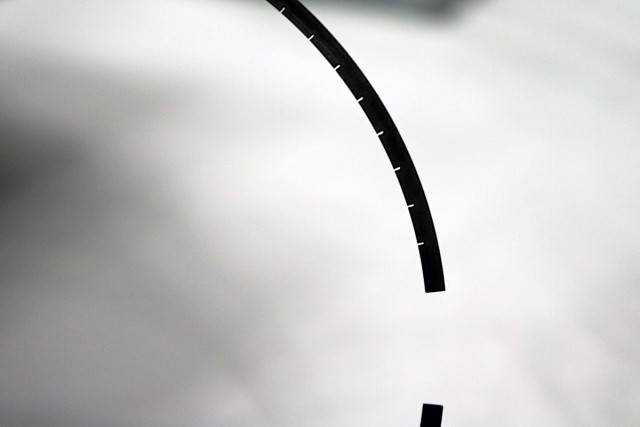

“Our total conform ring is easy to spot thanks to radial notches in it,” Jones began by telling us. “What that allows the ring to do is to totally conform by bending in any shape necessary to complete the seal between the piston and the cylinder wall.”

Jones continued by explaining how flexible this material is, and why it’s necessary. “By integrating those radial notches into our rings, it now allows the rings to flex and bend as necessary. It follows bore-distortion as the engine is running, and is especially useful in an aluminum engine block application. All types of engine blocks move, but aluminum is the worst offender,” he said.

Jones further explained that these specific rings not only reduce friction in the cylinder, but also the tension that the ring generates. “It’s a revolution and an evolution in ring design,” Jones concluded. Jones reminded us that while Total Seal Piston Rings [2] offers off-the-shelf solutions for most popular applications, you can always check its website or even contact them directly for any custom application needs for your engine build.