[1]With the price of chrome plating sky high these days, especially if you own a 50s or 60s vehicle that needs the bumpers and grille chromed, the side trim done, as well as the slew of smaller bits that nearly every mid-20th century car had on the dash and door panels, you’ll understand what I’m saying–chroming anything can amount to a substantial amount of money that must be set aside before you can take your dream ride out and show it off, and who among us has tried the “rattle-can chrome” only to be disappointed by the lack of crisp reflection?

[1]With the price of chrome plating sky high these days, especially if you own a 50s or 60s vehicle that needs the bumpers and grille chromed, the side trim done, as well as the slew of smaller bits that nearly every mid-20th century car had on the dash and door panels, you’ll understand what I’m saying–chroming anything can amount to a substantial amount of money that must be set aside before you can take your dream ride out and show it off, and who among us has tried the “rattle-can chrome” only to be disappointed by the lack of crisp reflection?

Not only is the expense creeping up and up, more and more chrome plating shops nationwide are closing their doors simply because of EPA regulations and their effect on the environment–talk about a dying breed! Hard chrome is not only expensive, but it’s getting difficult to find.

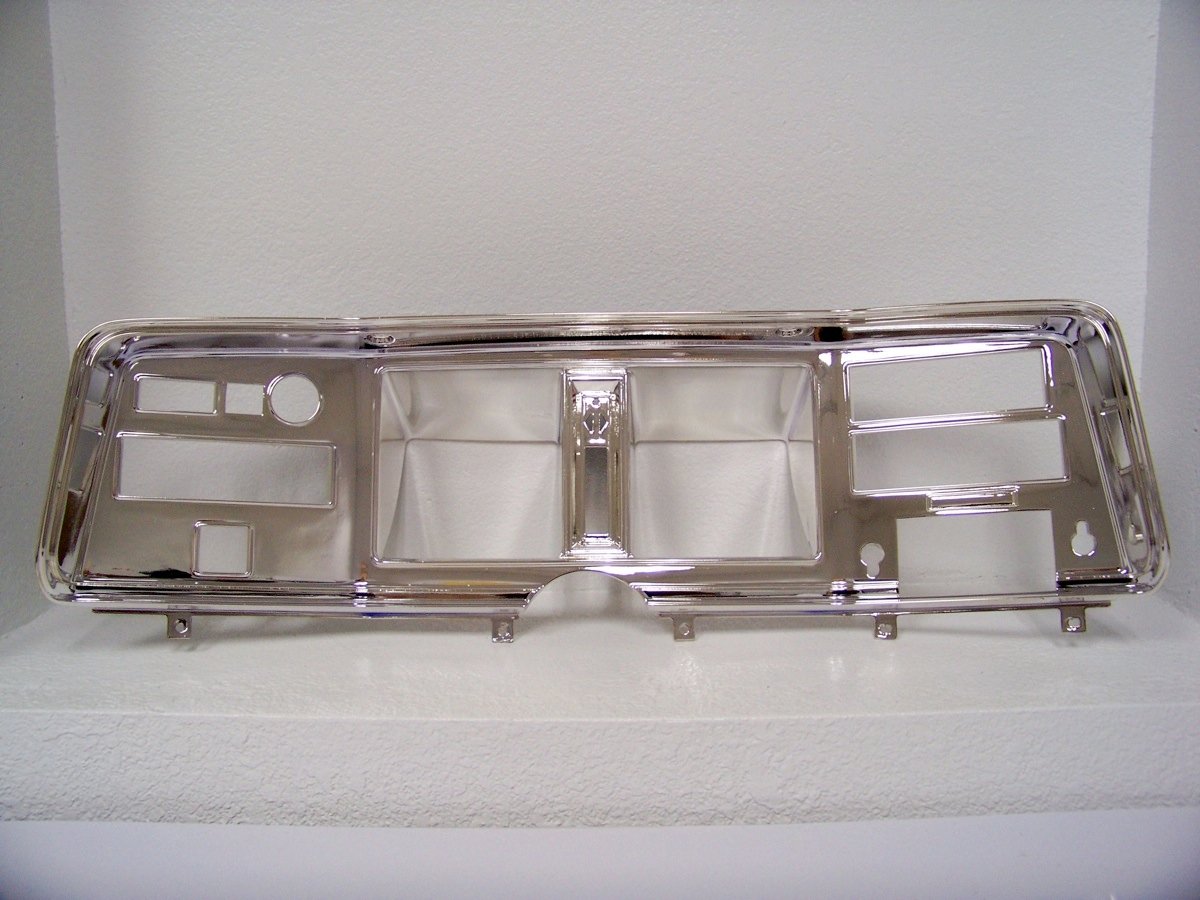

[2]There’s a ‘new kid’ in town that can make that process a little easier on the old bank roll. Xtreme Chrome Colorado in Brighton, Colorado has been in business for over four years and that alone sends the statement that a new alternative to traditional chroming is here and it’s working out well. What kind of chrome process you ask? Spray-on–before you dismiss this new type of chrome, before you quit reading, take a look at the picture to the right and tell me YOU can tell the difference.

[2]There’s a ‘new kid’ in town that can make that process a little easier on the old bank roll. Xtreme Chrome Colorado in Brighton, Colorado has been in business for over four years and that alone sends the statement that a new alternative to traditional chroming is here and it’s working out well. What kind of chrome process you ask? Spray-on–before you dismiss this new type of chrome, before you quit reading, take a look at the picture to the right and tell me YOU can tell the difference.

You’ve probably heard that the process is similar to paint, and while that’s true, each piece is handled as a custom project. Xtreme Chrome Colorado uses a proprietary process similar to paint, except that when they are finished “chroming” a piece, it’s near perfection. As a matter of fact, even those guys that work in traditional chrome places have a hard time differentiating it from their traditional chrome process.

Of course, the price of the process is not nearly as much as traditional chroming and like anything else, most of the expense of this process comes from preparation of the part. The prep has to be, not only good, it has to be great. You wouldn’t pay a painter to put a ten grand paint job over a rusted out hulk, would you? The price of the process depends on the condition of the part to begin with. The old finish needs to be removed and what kind of material the part consists of affects the price. Plastic, carbon fiber, and the like do not need the level of prep that metals do, especially 50 to 60 year-old metal. [3]

[3]

Sure, you’ll hear all kinds of pros and cons to the spray-on process, the negatives range from, “It’s not real chrome” all the way to, “It’s nothing but paint and it’ll chip.” While nearly everything you hear from spray chrome’s detractors is never good, there is always a bright side to every negative.

Kathy Palm purchased Xtreme Chrome in Longmont, Colorado, in 2011. Despite a set-back in 2013, when the St. Vrain River flooded her shop, she’s back to operating out of a smaller shop in Brighton and is turning out great pieces like nothing ever happened.

Several of her customers are helping her get back on her feet and Kathy is determined to stay in business, she’s done that for nearly four years now and that has to send a statement that spray-on chrome is here to stay.

But of course, the most important positive of spray chrome is that it will work on almost anything, plastic and carbon fiber included, as noted above. Among the items that can be chromed are architectural finishes, artwork, unique trophies, merchant and store displays, decorative glass, theatre, stage and set design pieces, motorcycles, bicycles, models (plastic-not human), any decorative metal and your most prized memento–whatever your imagination can conjure up!

Xtreme Chrome Colorado specialize in pot metal plating. Having said that, the actual chrome plating process for pot metal is hazardous at best and unless each traditional plater knows exactly how to do it, the part could end up being destroyed.

A close friend had gone through three sets of stock ’56 Cadillac headlight doors simply because the platers couldn’t deal with the factory pot metal. He’d spent more money finding and having those three sets shipped to him than the actual bumpers on his car cost via traditional chrome process.

Finding additional rare pieces after the first set is destroyed always adds to the eventual price of traditional chroming. Xtreme Chrome Colorado doesn’t have that problem and parts do not get lost in their vats simply because Xtreme Chrome Colorado doesn’t have any–a spray booth is as close as they get to ‘vats.’

Another one of the positives to the process is similar to spraying pricey paint in a body shop, it’s all about the guy behind the gun. Dale Petty, shop manager at Xtreme Chrome Colorado, has been restoring vehicles since his childhood, has over 15 years of auto body experience and paint work, and has dedicated himself to mastering the spray chrome process over the last five years. He is the guy who’s ultimately responsible for the finish on all the pieces that leave the shop. His dedication to making sure each piece is perfect is what makes the process so desirable. Like any other trade in this industry, owning the tools does not make you good at it, it takes “Xtreme” dedication.

Xxtreme Chrome Colorado has used the top two processes in the country: Spectra-chrome and Cosmichrome. According to owner Kathy Palm, both have different advantages (and disadvantages), but the final quality and reflection depends on prepping the part perfectly and trusting your parts to a shop that has long term experience using either custom application.

Plastic dash pieces can be done with Xtreme Chrome’s process and are not destroyed in the process. They come out “factory fresh” and you’ll never be able to tell the difference between Xtreme Chrome Colorado’s pieces from factory originals.

There are advantages to Xtreme Chrome Colorado’s processes. Number one is environmental–there is an increasing awareness of the health issues caused by the traditional chroming process, which is extremely toxic. Xtreme Chrome Colorado’s process uses pure silver and water to achieve their “chrome” and there is no toxic discharge of air pollutants or solids. The chemicals do not need to be replenished and transporting them to a waste facility is virtually non-existent in Kathy’s shop. About the only thing needing to be captured is the waste water. It’s captured in a 40-gallon evaporator and any residual silver that washes off as they coat pieces can be reclaimed. That’s about as clean and safe as any one process can be.

The process starts with either an exterior cast metal piece or smaller interior dash pieces that manufacturers added during the build process.

1). Each piece is then sand-blasted to remove as much of the old finish as possible.

2). Seriously pitted pieces, such as blistered pot metal pieces are filled with spot putty and hand-sanded.

3.) A polyester spray filler is applied and hand sanded.

4.) High quality primer and sealer are applied and hand sanded again with 1200-1500 grit paper until it is silky smooth.

5.) Once the piece is as smooth as possible, it’s ready to have the proprietary base coat sprayed on that’s needed for the silver to adhere to.

6). The piece is then sent to the spray booth, although there isn’t much overspray floating around as the process uses de-ionized water and silver nitrate to achieve the high gloss. [11]

[11]

7). After the de-ionized water has been sprayed, silver follows immediately and the piece is then rinsed with water again…that allows the silver to flow out and it’s left to dry for an hour.

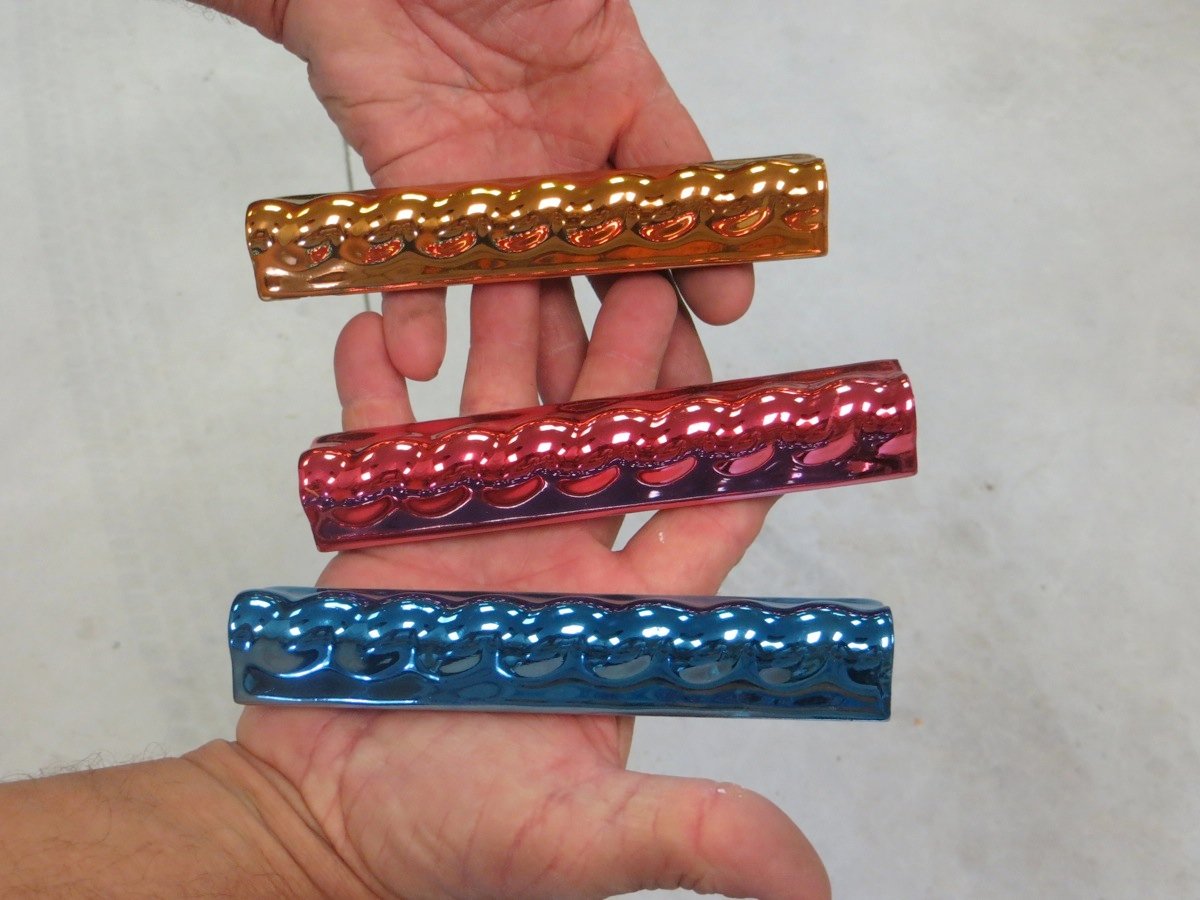

8). The final top coat is a urethane clear which melds the three layers together and protects the finish much like expensive automobile paint jobs. One really cool thing about the spray-on process is that the final coat can be tinted…there are seven basic colors: red, orange, yellow, blue, green, purple, and the newly popular “black chrome.” These colors can be mixed to create any custom color you may want to tint your “new” chrome items.

This Cadillac ‘Saber” wheel has been done with Xtreme Chrome Colorado’s process and we’d be lying if we told you it’s easier with a traditional chroming process–the polishing alone between each flute on each wheel would send the cost sky-high.

Be sure to check out Xtreme Chrome Colorado at www.xtremechrome.com [13] or call Kathy at 970-371-2555 or Dale at 303-717-1016 for more information. [14]

[14]