Automotive wiring has always been one of those “black art” segments of the industry; there are the know-it-alls, and then the know-nothings, and somewhere in between is where the broad swath of automotive enthusiasts reside.

Thankfully for those of us who “sort-of” get it, there are guys like Scott Bowers and the team at Ron Francis Wiring in Chester, PA. We recently had the opportunity to tour their facility and learn just how they put together some of the slickest wiring products known to man.

The History

Bowers, who started his wiring career repairing the mess under the hood of an old-school Datsun 280ZX back in high school, found his way into the business almost by accident. In the early ’90’s, Ron found himself in need of a general manager, and after interviewing Scott and a number of other people, settled on Scott as “the guy” to help Ron Francis Wiring get to the next level.

Ten years later, after helping the RFW team improve their brand, Bowers went off on his own to to start his own wiring company, The Detail Zone, which specialized in fuel injection harnesses. Bowers found his way back to Ron Francis Wiring seven years subsequent to his departure as the President and owner when Ron decided it was time to get out of the day-to-day operation of the business. Today, he has revamped the company’s line of products to offer just about anything you can think of when it comes to automotive wiring. Ron is still on the staff; although he doesn’t come to the shop every day he still answers the email inquires that come in through the shop’s website along with assisting Bowers and the RFW team with development work.

Left: Wires, wires, everywhere, and each one has been cut and crafted for a particular purpose. Left Middle: This machine marks each wire with a location (IGN, ALT, etc.) and uses a combination of heat and pressure to ensure the markings will remain throughout the wire's life. Right Middle: From 2-gauge to 20-gauge, this cutting head can handle both snipping and stripping the wire ends after the markings are imprinted. It's set up prior to each wire run to ensure that the strands aren't damaged during the cutting and stripping process. The machine also feeds and straightens the wire in the process. Right: There is no waste here; all of the excess wire and scraps are recycled.

Touring the Facility

During our tour, Scott took us through each section of the facility; from the beginning where they use specialized machinery to print each wire’s ultimate destination, to the end stages of packaging before the kits head out the door to customers all over the globe.

From Ron himself to Bowers to the third generation in Bowers’ son Kyle (who is one of the company’s technical representatives), the RFW team is full of car guys that are well-versed in providing wiring products that stand the test of time.

Ron Francis got his start providing Street Rod harnesses back in the day, and it’s under Bowers’ direction that the company has branched out to become one of the largest aftermarket wiring harness and related products suppliers in the country – their stuff can be found in the Summit Racing catalog along with that of Latemodel Restoration Supply for you Mustang guys. They are also the harness of choice for Factory Five Racing and provide the necessary harnesses to get the FFR machines up to speed. They are also focused on the racing market and have a number of things in development for that enthusiast segment.

For the uninitiated, taking on the task of wiring a restoration project, racecar, or weekend toy can seem like a terrible idea, but we’re here to tell you that it’s not nearly as difficult as it appears from the first glance – especially when you take a closer look into how the RFW team builds these parts and pieces for consumption and how simple they try to make the process for the end-user.

Each vehicle design has its own idiosyncrasies, and the amount of development time put into each harness kit the RFW team produces is extensive – they want to make sure you have the correct product, with enough wire and the correct connectors, to complete your project with a minimum of muss and fuss. To that end, they have quite a bit of proprietary machinery to perform specific tasks, and have custom-built other pieces to facilitate the easy construction of some of their unique harnesses.

Left: Various wire sections printed and bundled. You can see how the machine leaves the insulation intact to prevent the wire ends from separating. Middle: The 'Terminator' has the ability to crimp and process various types of wire ends from huge spools of material. Right: This particular end is a hot wire that will end up in a fuse block. The current travels through the bus bar section to feed all three terminals; the other side of the connection in the fuse block will run to the individual component.

Bowers explained, “When Ron was still here, he was focused on the Street Rod market, and since I’ve taken the company over we’ve been able to use some of the ideas we developed at the Detail Zone. We’ve expanded the Ron Francis Wiring brand, produced an accurate direct-fit 5.0L Ford engine harness that permits the engine’s installation into older vehicles, recently released the 4.6L Ford Three-Valve harness kit, and have gotten involved with the Factory Five cars.”

Coyote Engine Harness Development

The company also has plans to get onto the Ford Coyote train and is currently investigating what will be required to produce an aftermarket harness kit for those engines. One of the stumbling blocks he’s found is the availability of some of the Ford connectors; while the General Motors-based products are easy to procure, he spends a lot of time tracking down the Ford products to make those systems viable.

One of the things that makes their success possible is the staff; the tedious task of producing the same kits over and over again would eat up the abilities of a lesser staff, but Bowers raves about the folks that are part of his team.

Left: The staff is well-versed in the tedious work of harness creation. Middle and Right: Each of the individual wires to the 5.0L engine harnesses that RFW sells are hand-laid to ensure the proper length and connector style is used.

“I brought my staff from The Detail Zone in with me, and on top of all of the well-known products that Ron has developed over the years, we’ve continued to produce our well-known Telorvek fuel injection system designs that allow all of these late-model cars to run like they would from the factory. Each one includes diagnostic scan tool connections along with Malfunction Indicator Lamp circuits that will permit these systems to be serviced by any qualified repair facility,” he explains.

The Tools To Do The Job

The machinery on-site is dedicated to producing the best wiring systems available. All wire is automotive-grade TXL high-quality wire that is designed to withstand the rigors of a tough environment while remaining pliable and easy to work with over time. Each wire is hot-stamped with the intended location (lights, ignition, etc.) on the insulation – there is no confusion about what a particular wire’s intended use might be. Wires are sized properly for the current required by that type of circuit.

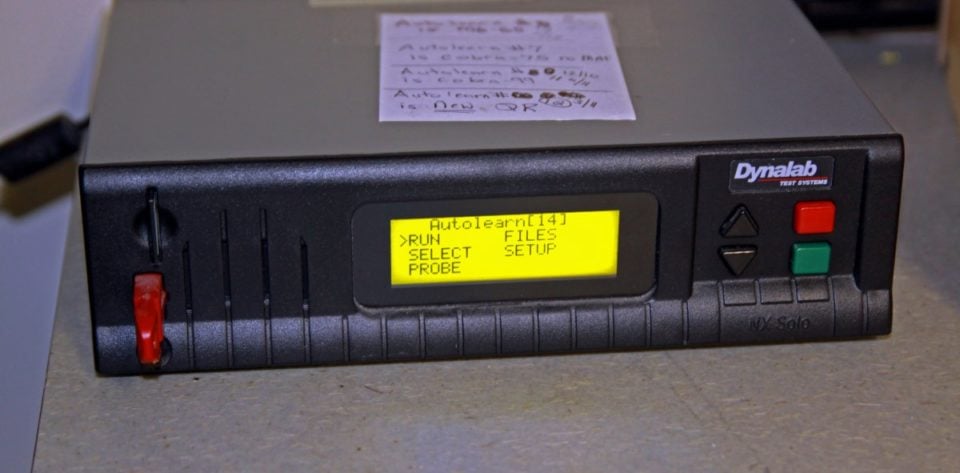

Left: Each complete kit is tested prior to shipping using this tester and a proprietary circuit board we can't show you here. That way, when your wiring kit arrives, you know everything is ready for installation. Right - This is an alternator bag for one of the various kits. Each individual component group has its own bag complete with instructions and all necessary connectors.

The wiring kits themselves are somewhat modular – there are only so many automotive alternator designs on the market, and many kits RFW produces use the same alternator wiring pack. The same goes for some of the other sensors like the coolant temperature sensor pack and the ignition wiring pack. RFW supplies enough wire to make sure you’ll be able to complete the job and have a bit left over, just in case there is an issue. Starter/distributor packs and cooling fan packs are also somewhat similar, so the amount of SKU’s needed can be kept to a minimum.

You can also purchase each type of wiring separately; you don’t have to purchase an entire kit to make use of their product line. Say you’re just looking to add an electric fan to your car – check out their website, and order one of the cooling fan control kits. Same goes for accessory wiring – each piece can be purchased by itself if that’s all you need.

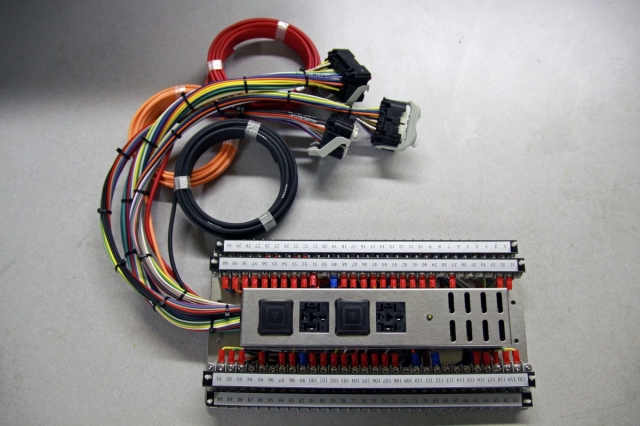

RFW’s Three-Valve Mustang harness allows the end-user to install a 3V Mustang engine into any vehicle. There are PCM connections, a MIL circuit, and enough electrical hookups to run everything else in the vehicle. The beautiful of this system is that the computer can be placed anywhere it will fit in the vehicle.

Their Latest 4.6-liter Three-Valve Modular Harness

We especially enjoyed the look into their 4.6L Three-Valve Mustang control center. The system comes with everything you need to swap a Three-Valve Mustang engine into whatever car you desire. It’s set up to use either a manual transmission or automatic transmission (with two different part numbers, so order accordingly) and can be used with either the factory return-less fuel system of an aftermarket return-style pump with return line.

You’ll be able to connect all of the factory sensors on the engine and transmission to a factory PCM (that they can supply, or you can purchase) plus you’ll receive wiring for the fuel pump, electric fan, and diagnostic port. You will require ECM programming, and they can provide that to you through an SCT tuner or you can head to your local dyno facility to have it done yourself. It can be purchased in kit form (so you can place the ECM wherever you want it) or a completely wrapped design that mimics the factory’s routing. They do recommend you call on both of those systems, mostly to ensure that you’re getting what you need correctly.

Here’s a nearly-finished kit awaiting packaging. As an order comes through, the specific ‘bags’ for the particular kit are picked form the warehouse and assembled into a neat and tidy box. The simplicity of the kits is nice to see.

In addition to the pre-designed wiring kits, Ron Francis Wiring offers so many various hard-to-find connectors, switches, buttons and associated hardware we don’t even have the space to get into here, but we hope you’ve enjoyed the quick look at what goes into making a Ron Francis Wiring kit so special. The team also travels the country to various events in support of their products, as Bowers has learned that having the opportunity to interact with the enthusiasts using the product is invaluable to his engineering efforts.

Check back with us soon, as we’ve got another article planned with Scott and the Ron Francis Wiring team on their Top Ten wiring tips that you can use to bring your project to life.