At the North end of Sioux Falls, South Dakota, amidst the acres of open fields, there’s a single building with no markings and a full parking lot. Inside the many walls that make up this hi-tech company we all know as Dakota Digital, you’ll find about 80 employees responsible for putting together some of the coolest high tech digital gauges for the automotive and motorcycle aftermarket.

At the North end of Sioux Falls, South Dakota, amidst the acres of open fields, there’s a single building with no markings and a full parking lot. Inside the many walls that make up this hi-tech company we all know as Dakota Digital, you’ll find about 80 employees responsible for putting together some of the coolest high tech digital gauges for the automotive and motorcycle aftermarket.

Dakota Digital has a full series of VHX gauges for Harley dressers, too. Owner Ross Ortman is a regular at Sturgis.

President and founder of Dakota Digital, Ross Ortman, started the company with aftermarket gauges that many enthusiasts might remember. They were digital gauges, with a vacuum fluorescent display that became popular with a lot of street rodders. They would later develop a new type of digital gauge that sales and marketing rep Greg Karpe says is, “digital input with an analog output.”

The VHX series took the digital readout and turned it into a typical, sweephand type of instrument, but still had the highly technical components of their earlier designs. The VHX series also took home the award for best interior component at the 18th Goodguys Nationals in Columbus this year.

Dakota Digital came home from Columbus this year with an award for the Best Interior Component at the Goodguys Nationals.

We stopped by to visit their 40,000 square foot manufacturing facility to see how they go about creating these unique gauges and other components specific to instrumentation, lighting, and electrical. We entered the building in the receptionist area where a vast majority of its products were on display. These were the same displays that one would find at car shows and trade shows all over the country.

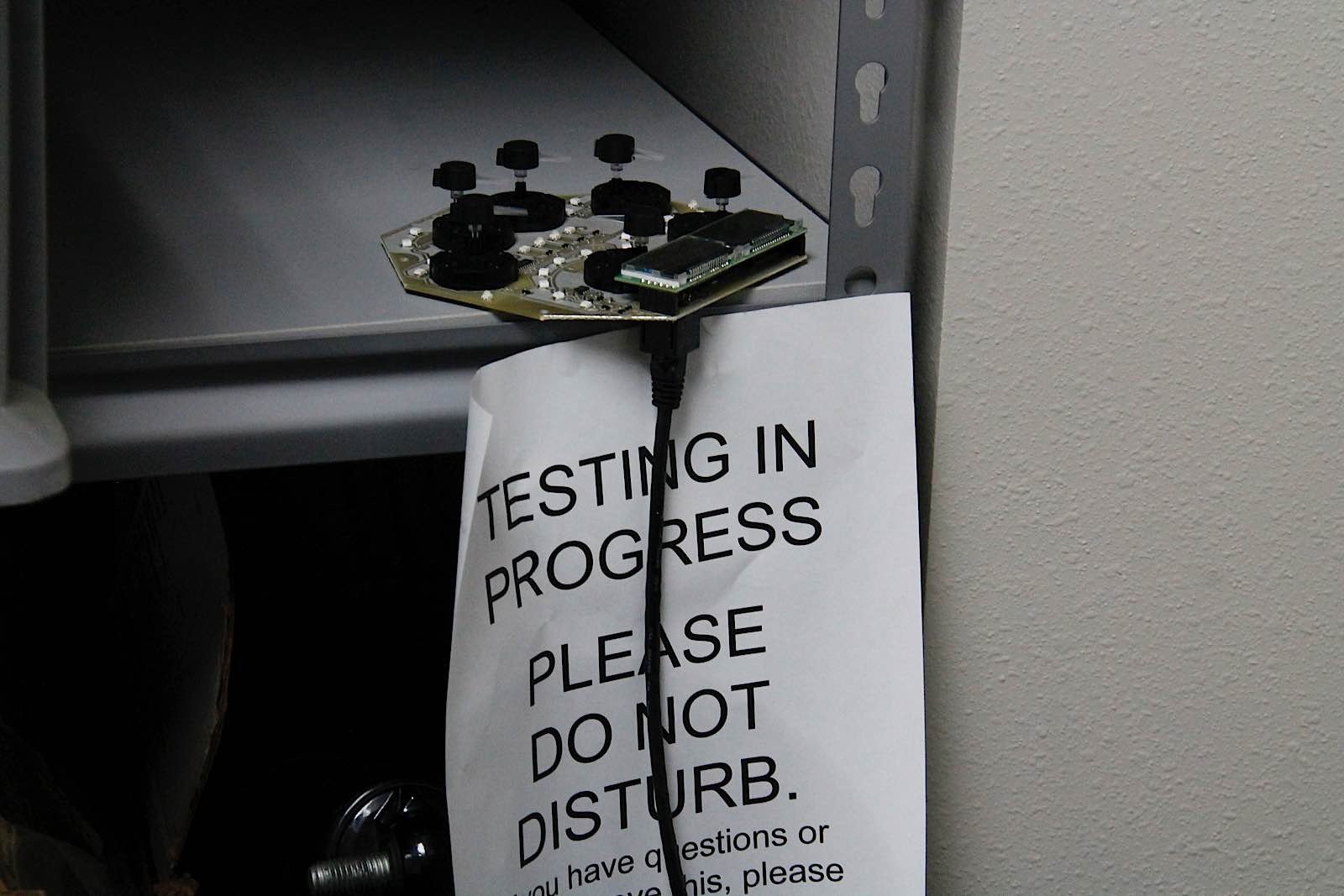

Don't touch that dial! Long-term testing is done on some of the products to see how well they'll hold up with repeated cycles. At the bottom, those needles have run over a million cycles and are still going strong. This test has been running non-stop for months.

While most of us think of instruments being a simple device that receives a 12-volt input and displays it to us with a small needle, Dakota Digital has opened their doors to show us all of the processes and components that lie between that input sender and the needle that provides the information. We asked sales manager, Scott Johnson to show us the details; we wanted to see every process that it takes to make a VHX instrument cluster.

Yes, it’s tiny but it packs a lot of punch in that little package. Two circuit boards are ‘stacked’ to hold all of the many components and LED lighting.

“An instrument system contains about 756 pieces, either raw components we purchase or assemblies we build to place within the housings,” Johnson told us. When you think about the size of an instrument cluster and that there are over 750 pieces that are manufactured or assembled to provide the data from your engine and transmission, that’s an astronomical number.

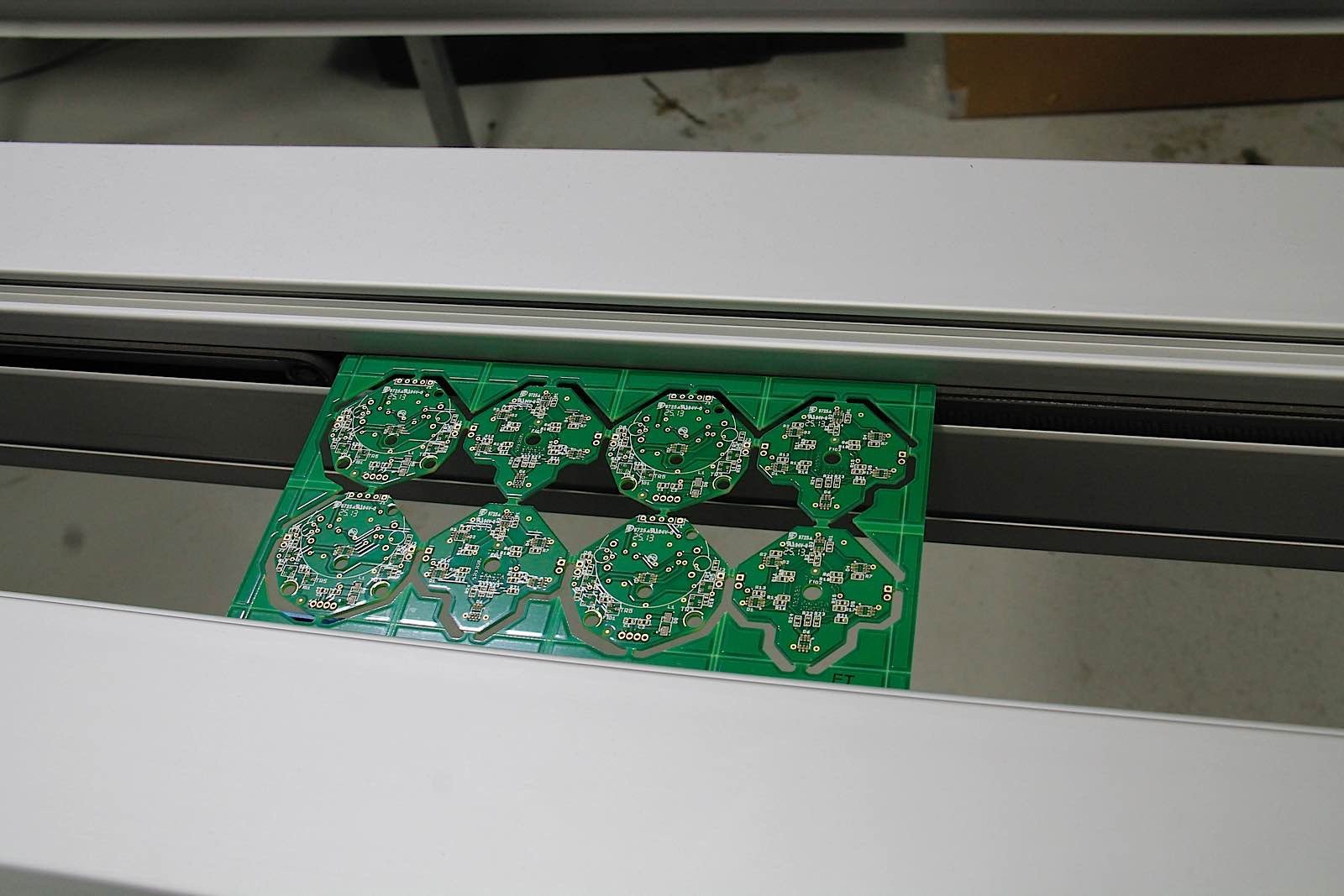

Of course, because Dakota Digital specializes in digital gauges and information centers, you can imagine how tiny many of those pieces are. Diodes, resistors, and rectifiers are just some of the hundreds of pieces that make up a digital information display. We were able to watch first hand how a small circuit board can be loaded into a machine that will apply a glue solder that will hold the minute components in place while they are being fed automatically onto the board.

Each of those resistors and tiny chips can reside on a roll of thousands of them that will be fed into the SMT Line, it’s a “pick and place” type of machine that puts these tiny components in place. A program tells the computer which spot receives which micro component and where it is inserted on the board. Several boards can be run through the line at a time and that helps to speed up the process of manufacturing.

Here we see the SMT Line, where the circuit boards are fed into the machine and places resistors and capacitors where they need to be.

Another part of the machine applies solder to secure them, and the tiny circuit board is ready to be inserted into a gauge. But the board is not ready for installation until it is thoroughly tested by one of the many staff members who puts each circuit board through a series of pass or fail tests that will let them know if it’s ready, or if it needs to be inspected and fixed.

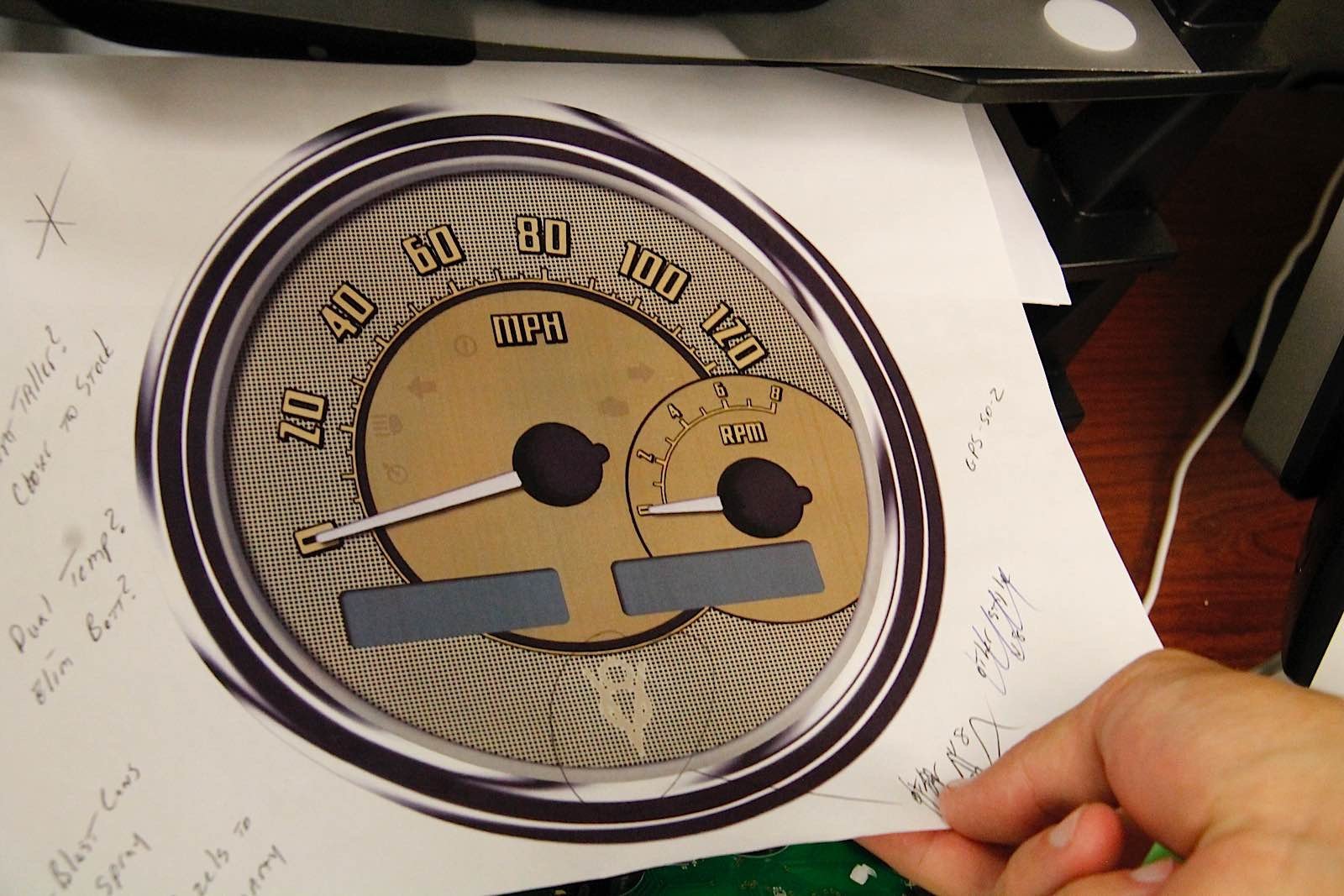

Another stop in the process to complete each gauge is the printing that lays down several passes on a large, UV tolerant ink jet printer. Since some portions of the gauge face allow the LED lighting to show through, they will get fewer passes on those areas than the rest of the gauge face. It takes several layers of ink, and the tiny indicators (such as turn signal and high beam indicators) will allow the back lighting to show through when it is illuminated, but will be barely visible with the lights off.

The gauge faces are screen printed, and the print head makes several passes, layering the ink to create the desired effect.

Many of the housings for certain gauges and components are made in house, too. To create a new component or cluster, a 3D printer is used for some of the prototypes. Once everything checks out, the design can be uploaded to a computer for the parts to be manufactured by a CNC machine. They can begin as a block of aluminum or plastic, and the CNC machine will go to work and create an insane mess as it carves out the shape of the finished component.

Johnson said they can collect much of the scrap from the machining process and recycle it, but some of it does end up as waste. They use a material called high density polyethylene (HDPE) because of its excellent properties to remain strong for tooling and assembly and its resistance to the extreme temperatures inside a vehicle.

Though there are quite a few machines to do some of the work, much of the testing and assembly is done by hand.

Each of the gauges might have components that are assembled or screen printed by machine, but the final assembly is always done by hand. Each gauge is run through a series of tests, and then they’re plugged in to make sure they work properly prior to being packaged up and shipped out.

There’s so much going on inside the many walls of Dakota Digital, and it’s truly amazing to see how its products are manufactured and how much goes into each instrument cluster or gauge. You can visit the Dakota Digital website and see the many products that they offer, but to see the many components that they use to make those products, we provided a huge gallery below so you can get a close up view of all the marvels and mystery that we got to see during our visit.

Always willing to help out a builder with a custom set of gauges, Dakota Digital keeps busy with new designs, and custom applications.