With the foundation for our ’36 Ford Project Flat Out well underway thanks to the craftsmen at TCI Engineering, Baer Brakes, and Currie Enterprises, our thoughts turn to the underhood area and the motivation behind this build. This was the driving factor that helped pave the way for the “modern tech” theme suspended under a “classic street rod” body.

The Motivation

Rod Authority editor Mike Alexander had quite the decision to make when it came time to plan out the powertrain for this project – would this wicked frame-dragger use a flathead Ford as was originally installed between the framerails? What about reliability and longevity – how about a small-block Chevy, as so many other hotrods have, or even an LSX powerplant, as those swaps seem to be the way to go nowadays?

The 5.0L Coyote engine boasts 412 horsepower and 390 foot-pounds of torque, and combined with some of the other components in this article make for one of the best swap engines on the market today.

Of course not – the plan from the get-go was to keep this baby Ford-powered while throwing a host of modern technology into the mix. Pairing classic custom looks with new-school tech to build the ultimate street rod, Alexander opted for something a little more daring. The 5.0L V8 Coyote engine as found in Ford’s current Mustang has simply exploded into the enthusiast marketplace, with these Coyote crate engines being offered at a very reasonable price, Alexander knew his decision was quite easy. It was time to order up a brand-new Coyote crate engine straight out of the Summit Racing catalog (Part # M-6007-M50) along with the rest of the gear to make it run.

The Summit Racing Coyote Combo gives a whole new meaning to the term “crate engine” and comes with all of the components needed to help with the swap.

Summit Racing has taken all of the “guess work” out of this crate engine by pairing it with the needed accessories to swap the Coyote into any custom vehicle. Their full “Coyote Combo” (Part # SUM-CSUMFFC12) features:

- Ford Racing 5.0L 412 hp 32-valve DOHC crate engine

- Ford Racing 5.0L 4-valve modular crate engine control packs

- Moroso 7 1/2 qt. oil pan with oil pump pickup

- Vortech Engineering T-Rex fuel pump

- AEM adjustable fuel pressure regulator

- Liquid-filled fuel pressure gauge

- Powermaster XS torque starter

- Ford Racing 5.0L modular alternator kit

- Ford Racing speedometer adjuster

- Ford Racing composite intake manifold cover

With the choice of “new muscle” under the hood of Flat Out means she’ll start right up, every time, get great fuel mileage, and will still pack quite the punch with a whopping 412 horsepower at 6500 RPM and 390 lb-ft of torque at 4250 RPM – numbers that match or eclipse the ’03-’04 Cobra’s supercharged powerplant, and a great starting point for Project Flat Out.

Of course, we’ve got a few cool upgrades planned that will boost the as-delivered power level, but before we get ahead of ourselves, let’s talk about what makes the Coyote engine such a special piece and perfect for this build. The most notable feature is the overhead-cam setup, scienced out on the Modular family of engines from the get-go.

Overhead Cams & Modular Design

Initially, the Overhead Cam design appeared in the 1996 Mustang GT’s 4.6L engine in a Two-Valve configuration, and the Four-Valve version made its debut in a Mustang platform in 1999 in the naturally-aspirated design. Later versions of the Cobra found supercharged boost in 2003-04, and the Four-Valve design was also at home in subsequent versions of the GT500 before being repurposed and redesigned to work in the 5.0L application, albeit with some changes.

Ford toyed with oil-pressure-actuated variable-timing camshafts for the first time in the Three-Valve Mustang powerplant, found in the 2005-10 Mustang, using a cylinder head with two smaller intake valves and one large exhaust valve. The chief reasons for the application of variable timing were to salvage emissions and fuel-mileage requirements, and the development of the system evolved into the current design found in the Coyote engine.

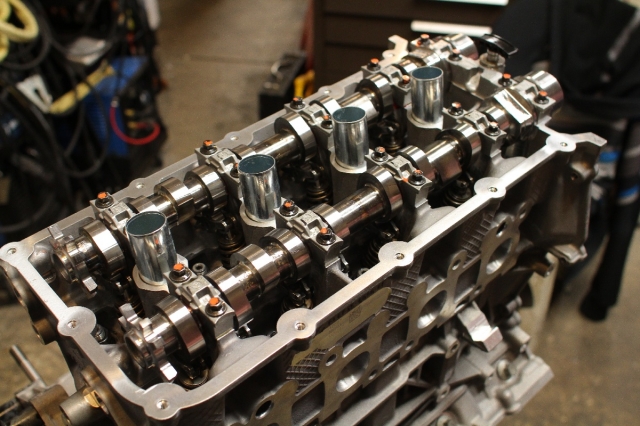

Factory Ford cam phasers (seen here on the end of each camshaft) are oil-actuated and provide up to 50 degrees of advance on the intake camshaft and 50 degrees of retard on the exhaust camshaft. This results in large improvements for power and torque with the added benefit of emissions improvements.

In the Coyote, all of this development work came to a head (pun intended), as Ford uses what they call Ti-VCT (Twin Independent Variable Camshaft Timing) to actuate the valves in the four-valves-per-cylinder design. Ti-VCT uses electronically-controlled hydraulic valves that direct high-pressure engine oil into the camshaft’s phaser cavity, which permits adjustment of timing for both intake and exhaust camshafts. By using the powertrain control module, a signal is directed to a solenoid to move a valve spool that regulates the flow of oil, and the valve timing is changed though the spool to advance or retard the camshaft.

Summit Racing Coyote Combo Pack

Summit Racing Combo – SUM-CSUMFFC12

Teaming with industry heavyweights, Summit built the perfect hot rod “swap package” by pairing the Coyote with the extra components needed to get you up and running, including:

- Ford Racing 5.0L 412 hp 32-valve DOHC crate engine

- Ford Racing 5.0L 4-valve modular crate engine control packs

- Moroso 7 1/2 qt. oil pan with oil pump pickup

- Vortech Engineering T-Rex fuel pump

- AEM adjustable fuel pressure regulator

- Liquid-filled fuel pressure gauge

- Powermaster XS torque starter

- Ford Racing 5.0L modular alternator kit

- Ford Racing speedometer adjuster

- Ford Racing composite intake manifold cover

In the factory application, the intake camshaft is at the full retard position by default and can be advanced by the computer up to 50 crankshaft degrees, while the exhaust camshaft position is at the full advance position and is retarded up to 50 crankshaft degrees depending upon situation.

This allows the engine’s computer to “tune” the cams to the best centerlines for any throttle position by using the internal lookup tables for the individual conditions. At low-throttle cruising speeds, the intake camshafts may be retarded substantially to reduce pumping losses, while the exhaust can be independently tuned for a longer power stroke. By being able to control the overlap and move the exhaust in the opposite direction of the intake camshaft, these two advantages are where the Coyote really shines over the earlier Three-Valve design.

The result is greatly improved power and torque, especially at lower engine RPM levels, and provides the added benefit of improving fuel economy and reducing emissions – which is truly a win-win scenario all around. Using variable cam timing on the exhaust side means that the OEMs can do away with exhaust gas recirculation (EGR), achieving lower inlet charge temperatures and a more efficient engine in the process.

How does all this apply to Project Flat Out, you might ask? Well, most importantly it means that we’ll be installing an engine that offers the latest and greatest in technology advancements, ensuring that our project vehicle will give us a great performance base with room to add our personal touches to spice her up a bit.

Coyote’s Features And Benefits:

With two camshafts per cylinder head, there’s lots going on under a valve cover on the Coyote. The overhead-camshaft design means there are no heavy rocker arms or pushrods to weigh down the valvetrain.

- Lightweight aluminum cylinder block

- Cross-bolted main bearing caps

- Thick main bearing bulkheads

- Deep-sump 8-quart oil pan

- Optimized oil drainback and windage control

- Tuned composite intake manifold

- 80mm single bore drive-by-wire throttle body

- 4-Valve per cylinder aluminum cylinder heads with roller finger follower for reduced friction

- Engine mount bosses and bellhousing mount patterns common with 4.6L modular engines

In Control

All of this innovation begs the question, “So now I’ve got a high-tech engine with all of the latest whizbang parts inside, can I just install a carburetor on top and go?” Well…not exactly. Although our sister site StangTV is building a Coyote engine project to make use of a carburetor on top and break all of the rules, but that’s not exactly what we’re looking for with our build and defeats the purpose-built “reliability” and drivability factor that we’re after here.

Thankfully, Ford Racing Parts has come to the rescue by offering their 5.0L 4-Valve Coyote Engine Control Pack (included in the Summit Racing Coyote Swap Combo) to make the swap an easy one. The control pack comes with the PCM that includes a calibration from Ford Racing, a throttle pedal that works properly with the Coyote’s drive-by-wire throttle body, a built-in OBD-II diagnostic port, 2011-14 Mustang air intake assembly, mass airflow sensor, and all of the necessary wiring and harness adapters.

Ford Racing’s Coyote control pack comes with the majority of the hard parts you’ll need to facilitate your swap – a PCM and wiring harness, oxygen sensors, and a drive-by-wire throttle pedal. It also comes with an inlet duct assembly to fit a Mustang, but you’ll most likely have to follow the instructions to properly fabricate your own.

Providing a one-stop-shopping experience that will allow you to get your Coyote into its new home with a minimum of muss and fuss. There are aftermarket tuning solutions for those also interested in a stand-alone engine computer like F.A.S.T.‘s XFI 2.0 – which we might utilize depending on our induction choices to add some hot-rod flair and style under the hood of our ’36 – more to come in Part 2 of this engine build.

Installation and Upgrade Options

Exhaust manifolds are a slightly sticky issue, as the headers that come with the engine are designed for the late-model Mustang and likely won’t work in an earlier application. Ford Racing Parts offers a set of cast-iron manifolds that will bolt right up and allow you to fabricate your own exhaust from the termination point and their block-hugging design will work well in an application where there is limited room. As for our build, you’ll have to wait and see what Image Street Rods has up their sleeves for our custom header and exhaust system for Flat Out.

The accessory drive solution from Turn Key Engines keeps all of the components tucked in tight to the engine for clearance in size-limited applications.

In addition to the previously mentioned items, a few other things should be noted in the quest for blending old-school with with new-school wizardry. As the 2011-up Mustang has electric power steering, there are no provisions in the accessory drive for a hydraulic power steering pump. However, Turn Key Powertrain has just the solution.

In addition, you must use an electric fan, as the Coyote doesn’t have any mounting provisions for a mechanical fan driven via the water pump.

Since the Coyote powerplant enjoys such an immense aftermarket presence thanks to its installation in the Mustang, performance parts are many – and widely available. We’re looking at a number of options for our machine, including a custom induction setup that will incorporate four pairs of throttle bodies to mimic the Weber IDA downdraft carburetor look of years gone by, along with a new intake manifold to match up with the Coyote’s ports.

However, instead of a bunch of finicky carburetors, the Inglese setup has the modern touches of fuel injection to prevent shoddy throttle response and poor drivability. A properly tuned induction setup can flow over 2800 CFM as a system, which is plenty of airflow for the Coyote to ingest, especially in a naturally aspirated setup like ours.

We have not determined which of Comp Cams’ grind designs we will be using in our Coyote, but rest assured they’ll provide a nice increase in power.

Another upgrade that is definitely worth considering is a camshaft upgrade on both the intake and exhaust sides; although it is not a task for the backyard installer, it’s one that’s well worth the time and expense to have done properly.

Comp Cams offers a number of different grinds (Summit Racing Part #s 191060, 191100, 191160 for naturally aspirated engines), and the nice thing is that you don’t need to go in and change the valve springs to use any of these profiles. Although, a set of Comp’s Phaser Limiters (Part # 5492) is required with the camshaft upgrade, which will prevent the valves from contacting the pistons at the extreme ends of the camshaft’s operating range.

With the added lift and duration figures built into the designs, the Phaser Limiters allow independent control over the intake and exhaust centerlines. They physically limit the cam phasing to 25 crankshaft degrees while allowing maximum intake advance and exhaust retard.

Making It Yours

As our Total Cost Involved chassis has plenty of room for the Coyote engine, we don’t anticipate many issues with fitment into the chassis even though the engine is physically one of Ford’s largest power plants (the real fun will come when we put the sheetmetal back on!).

Our TCI Engineering chassis (seen here in an unfinished state) has plenty of room between the framerails for our new Coyote engine. Stay tuned as we build the trans and engine mounts to fit our Coyote and TCI 6X trans combo.

And for those of you who share our passion in giving your Coyote a touch of the past, Troy Ladd of Hollywood Hot Rods has just the solution. He’s found that the SOHC “Cammer” valve covers will bolt up with a bit of modification. “We make adapter plates to use the SOHC valve cover out of 3/16-inch aluminum that bolts to the head, and then the covers bolt to the plate. There’s also an aluminum inner structure that keeps the oil off the coils, and the coils can live underneath the valve cover. The coil trigger wires also come out the old spark plug holes so it looks authentic,” he explains. “We had one of those valve covers laying around and thought it would look cool.”

Hollywood Hot Rods has a number of Coyote-powered rods running around, and Ladd finds the Coyote engine an excellent choice in many applications. He explains, “The fuel injection is going to be much more efficient and just work better – you get more power, better gas mileage, and all of the advantages of modern technology, but they look stupid in factory form. So if you can make them look cool while you’re at it, why not?”

Left - HHR's tweaked Coyote engine in the 1940 Ford they created for Street Rodder Magazine. Right - HHR's '63 Comet with Coyote power. Images Courtesy Hollywood Hot Rods

The Coyote engine has a healthy power output – much more than a traditional hot rod engine for what amounts to a fraction of the price in many cases. “You can get 400 horsepower without even trying, where to get something to make that kind of power from an older engine takes a lot more effort and money. It’s an amazing marvel of technology, and if you can make it look the part for a hot rod, it’s nice to be able to take advantage of the modern amenities, reliability, and power,” adds Ladd.

In a hot rod, you have to be a bit more creative, as you need to balance form and function. – Troy Ladd, Hollywood Hot Rods

Troy Ladd and his team are one of the first builders to be able to make the Coyote work with a standalone engine management system, using a custom injection design and the F.A.S.T. XFI fuel injection system. “Fuel injection is easy – all of the inputs and outputs are fairly common across the board, they are just standard inputs and outputs. Once you get away from the fact that it’s a Ford or Chevy engine and just realize that it needs a certain amount of inputs (temperature, RPM, TPS, etc.) and outputs (coils, injectors, etc.) to function properly, it just works, and that was the mindset we used,” he explains.

HHR received a Coyote engine before they were even released for production in the Mustang. “We’ve done a few of these at this point – we’re actually the first to ever do a Coyote in a street rod. When we got it, we immediately tore the engine apart, threw all of the plastic out, and made it look like a cool vintage engine and put it in a hot rod. It was a design experiment and challenge, and since then we’ve done them in a few other cars because people saw them and wanted a similar treatment. This is the modern engine of choice for Fords, but it’s not right for every car – it depends on what you’re doing,” Troy concluded.

Getting ready to mate to our TCI 6X transmission and with the Coyote to be set in the framerails for mock-up.

Wrapping Up

As you can see, it’s a lot to take in when you’re planning a build like this – lots of details and plans, and the more thought you put into laying the groundwork, the better your end product will be. If one thing doesn’t fall into place, it could derail your plans halfway through the project. But with a solid plan, research, and the right team – that vision can be achieved, and the 450-plus horsepower fuel-injected engine between the rails of your street rod will be the icing on the cake.

We’ll be covering more of the nitty and gritty details in Part 2 when we begin to tear into the engine and wrap up with the final install into Project Flat Out, so stay tuned right here on Rod Authority to see what’s next!