Our project car, Sucker Punch, a 1954 Chevy Bel Air with a Blueprint Engines 383ci short-block topped by a Edelbrock DIY Performer RPM E-TEC 435 upgrade kit and a Hughes Performance TH350 transmission bolted on is a far cry from the factory stock 235ci Blue Flame inline 6 with two-speed Powerglide auto transmission. When you add in a complete TCI Engineering front and rear suspension, it’s easy to see how fitment issues with things like an exhaust system could be problematic with this custom combination. We quickly solved those issues with Ultimate Headers and Flowmaster Exhaust.

These new headers are engineered muscular elegance. – Jim Browning

“Flowmaster was an easy choice,” he added. “We love the muscular sound of the HP2 mufflers and their exhaust kit took out all of the guess work of finding the right bends.”

The Factory Stock System

Because the first generation Bel Air featured the legendary “Blue Flame” six-cylinder, with the four exhaust ports, the stock exhaust manifold couldn’t be used–nor would anyone that was looking for performance want to–the siamesed ports restricted flow and robbed power, which is the opposite of what we were after.

Ultimate Headers

Ultimate Headers, headquartered in Berea, Ohio, has brought an entirely unique line of headers to the automotive performance market. The company is led by Jim Browning, best known as the Founder and past President of Corsa Performance.

Browning describes the new headers as “engineered muscular elegance.” The focus with these new headers is combining form and function to address key areas of concern. Using the best modern engineering practices, along with cutting-edge CAD, the newest manufacturing technologies and aircraft-grade materials, the Ultimate Headers team’s products have brought a whole new perspective in terms of appearance and functionality.

Ultimate Headers’ weld together Flange and collector kit with their SBC exhaust header helps create the ultimate custom exhaust.

For small-bock Chevys, Ultimate Headers has designed a header that is perfect for custom applications with a classic block hugger style. Featuring a center exit, below you find a series of highlights afforded by the Ultimate Headers exhaust header.

Features of the Ultimate Header’s SBC Exhaust Header:

- Ultimate Headers’ investment cast 316L stainless steel head flanges with high strength 321 stainless steel tubes for heat resistance

- Unique investment cast 316L stainless steel collector delivers increased exhaust flow and exits parallel with the oil pan rail

- Header design features 1 5/8-inch tubes with 2 1/2-inch collectors

- Available in polished, satin, or ceramic coated headers in black or silver

Ultimate Headers’ exhaust manifold not only has a custom “muscular elegance” appearance, it is also manufactured with tough material that has great heat transfer properties and corrosion resistance.

“When we started this program, we had the vision of a product which projected quality in just about every aspect,” says Browning. “We wanted a product that was extremely durable, but also had a sterling appearance that was highly recognizable and had functional advantages over the existing products that were in the marketplace.”

While aiming for that “sterling appearance” that Browning mentioned, the company also found performance in their material and finish processes. It is amazing how small changes in heat transfer effect overall performance and Ultimate has the heat transfer covered with the ceramic coated header finishes. Ultimate uses 316L grade stainless steel, which is known to have better corrosion resistance than most other grades of stainless steel as well as its reputation for toughness even down to cryogenic temperatures.

Manufacturing an exhaust header with functional advantages while keeping the “block hugger” design was a goal of the Ultimate Headers’ team.

Better heat transfer properties, corrosion resistance, and tougher material are reason enough to select Ultimate Headers but when you figure in the design and engineering that go into each product, it’s a no-brainer. “Our mission was to design and manufacture headers using state-of-the-art engineering tools such as Finite Element Analysis to optimize functionality, while delivering that style we refer to as muscular elegance,” explained Browning.

The header kit includes two-header assemblies, ARP 12-point fasteners, Mr. Gasket MLS header and MLS collector gaskets.

Small-Block Chevy Flange & Collector Kit

Ultimate Headers’ flange and collector kits are not simply a punched out flange add-on for an exhaust manifold. These kits are designed with the same engineering techniques as the exhaust headers are, and they use the same high quality material as well.

Features of Ultimate Headers’ SBC Flange and Collector Kit:

- Feature aerospace-derived engineering techniques and metallurgical processes

- 316L Grade Stainless Steel delivers a very strong casting with heat and corrosion resistance

- Flange rib design gives exceptional strength and reduced weight

- A perfect match with Ultimate Headers 316L Stainless Steel cast tight radius header elbows

- Runs cooler due to increased surface area, thus further reducing tendency to warp

- Available in vibratory polished, satin, mirror polished, and mill/cast finishes

Ultimate Headers' flange and collector kit includes MLS gaskets and premium flanges to connect the system together.

We selected the polished version to go with our custom exhaust system. The polished look will work well with some future chrome upgrades that we have planned for the engine and engine bay. The design and material used in manufacturing make the Ultimate Headers’ flanges and collectors lighter than typical flat stock material, yet exceptionally strong. This strength allows the flange to deliver exceptional clamping force to the cylinder heads. The unique design also offers a distinctive custom look to highlight any exhaust system.

Flowmaster U-Fit Dual Kit

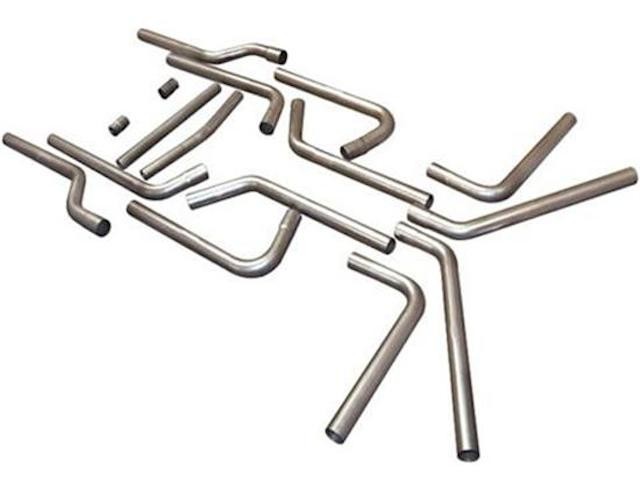

Flowmaster’s U-Fit dual kit is a universal item, meaning that it is not a direct fit, and there will be minor fabrication required for proper fitment. This is what makes it perfect for custom exhaust systems. The 16-piece dual pipe kit simplifies making an exhaust system for vehicles where the engine, transmission, or chassis components are not a boring cookie cutter combination. The mandrel bent 16-gauge aluminized steel tubing comes with convenient slip-fit connections for ease of assembly. It’s simply a matter of measuring and cutting the end opposite of the slip-fit connection to get the perfect fit.

Flowmaster’s U-Fit dual kit (Part #15936) is a 16-piece kit that includes everything you need for a 2 1/2-inch exhaust system with mandrel bends, except the mufflers – which you can also pick up from Flowmaster.

Features of the Flowmaster U-Fit dual kit:

- Mandrel bent 16-gauge aluminized tubing

- Front adapter pipes/intermediate pipe/H-pipe

- Over the axle pipe with optional tailpipe exit

- Slip fit connectors for easy assembly

The U-Fit dual kit is much like designing your own custom system and should be installed the same way a custom designed and custom fit system is typically installed. We recommend initially assembling the pipes on the floor and layout the system before making any cuts. Examine all the possibilities before beginning on the vehicle. On the first pass through, we recommend leaving the pipes a little longer, then measure and trim the pipes for the final fit.

When laying out the exhaust pipe runs, we found it best to work on one side at a time. Place the muffler in the desired location then lay out the rest of the pipes starting at the engine. Once we were satisfied with the design of the system, we trimmed the pipes and tack welded them in place. Prior to welding the parts together permanently, we checked for clearance around the driveline, floorpan, fuel and brake lines, and any other components that could interfere with a trouble free exhaust system, then performed the final welding.

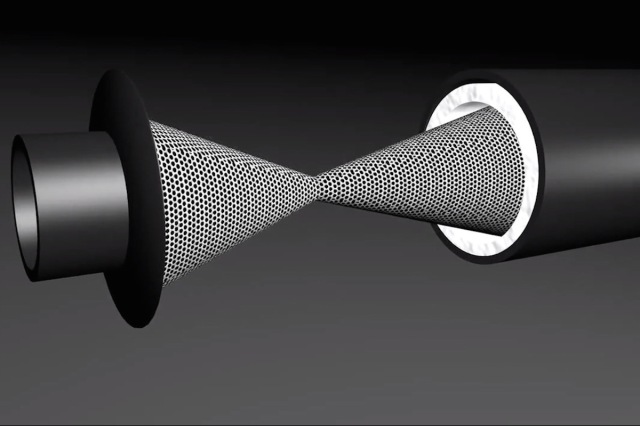

Flowmaster’s classic laminar flow system inside the Super HP-2 mufflers punctuate our custom exhaust system with sound.

Flowmaster Super HP-2 Mufflers

We chose to use Flowmaster’s Super HP-2 mufflers in our dual exhaust system for it’s classic styling and hotrod sound. Flowmaster’s laminar flow mufflers have proven performance benefits with a classic sound that is recognizable to any gearhead. The Super HP-2 mufflers are a combination of Flowmaster’s classic HP-2 laminar core and a new compact square outer case. This results in the same great performance and moderate tone in a new stylish case that is available in either a 409S stainless steel case or a polishable 304S stainless steel case.

Flowmaster’s Super HP-2 mufflers with the stainless steel outer construction and laminar flow inner construction eliminate the unwanted tones but allow the classic hot rod rumble to flow. We used our Millermatic 252 MIG welder to join the exhaust tubes. Miller’s MIG or TIG machines work well against the stainless steel exhaust material.

Features of Flowmaster’s Super HP-2 Mufflers:

- Stainless steel construction

- Dyno tuned for maximum performance

- Patented laminar flow technology

- Lifetime limited warranty

- Made in the USA

We selected the polishable 304S stainless steel (Part #12518304) with a 2 1/2-inch input/output. The laminar flow technology works via the use of two opposing conical shaped structures inside the muffler. This technology creates at deep powerful sound, however it maintains lower decibel levels, allowing owners to enjoy the legendary Flowmaster rumble. Their “cool shell” technology also helps this muffler retain heat inside the muffler case, leading to higher thermal efficiency. This also means that the exterior of the muffler is cooler, meaning it can be placed in tighter spaces without the worry of excessive heat damaging nearby components or finishes. Perfect for what we wanted to do with our Bel Air.

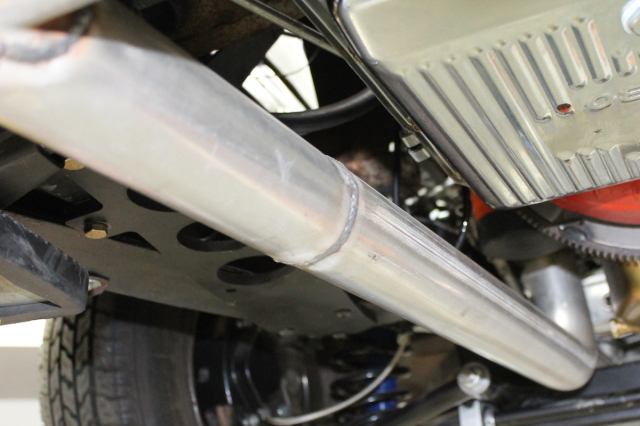

Our custom system with components from Ultimate Headers and Flowmaster provided the ability to run a dual exhaust in a chassis that had a complete suspension and drivetrain upgrade, yet had enough flexibility to position the exhaust where there was plenty of clearance from other components and the asphalt.

Taking a Final Look

Once we had the system in place and fully welded, it is mandatory that you step back and admire the results. Fortunately for us, we have a lift in the shop and can take in the whole project without having to lay on our backs in a driveway with the car on jackstands. This leads to a round of high-fives and pats on the back with the ultimate question being asked, “What does it sound like?”

Lowering the lift, our crew fought for the privilege of being the guy that started up the project car. Winner of that prize was our shop fabricator, Dean Jigamian, who described the event as “Biblical.” We had to agree with Jigaman’s one-word response with a single-word response of our own, “Epic.”

Flowmaster’s U-Fit kit allows fabricators the flexibility of running dual exhausts with an H-pipe in an easy-to-layout and assemble kit.