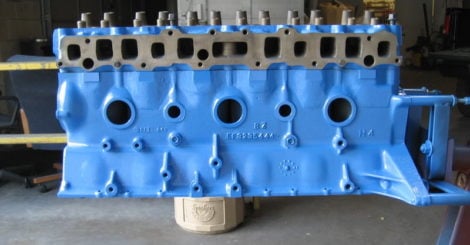

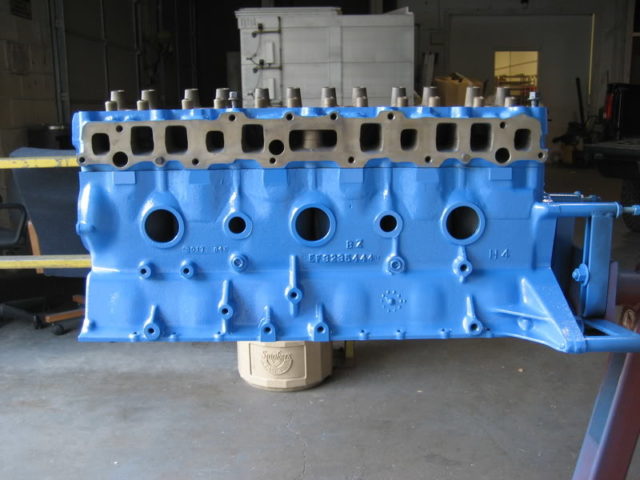

Powder coating is an awesome way to give select automotive parts a high-impact color or finish, which helps set your vehicle apart from the rest of the competition. Not only does it allow you to run color schemes throughout your car, even into the engine bay, it can also help protect your components from unsightly wear and give your build an all-over finished quality not seen with many other finishes. But how does it work? Well, according to Pete’s Hotrods, its as simple as a colored powder with a chemical makeup being drawn to the component you want to powder coat. Check out the process and different types of powder coating in the video above.

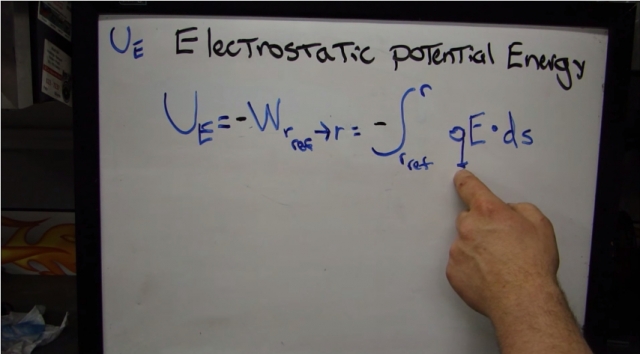

Call it automotive science or a throwback to chemistry class, the logistics behind the powder coating process go back to behaviors of atoms, complex mathematical equations and honestly, the same exact stuff half of us zoned out from in high school science class. The overall process of powder coating is actually quite simple to understand and pretty interesting once you get down to it.

Call it automotive science or a throwback to chemistry class, the logistics behind the powder coating process go back to behaviors of atoms, complex mathematical equations and honestly, the same exact stuff half of us zoned out from in high school science class. The overall process of powder coating is actually quite simple to understand and pretty interesting once you get down to it.

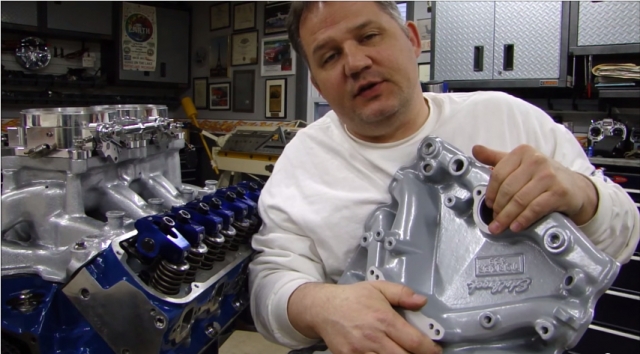

To start us off, Pete from Pete’s Hotrods (and Pete’s Garage) lays out the differences between the many types of powder coating powders there are to choose from.

From polyester varieties to epoxies, fluorpolymers and silicones, the basis of your powder is important due to their overall finish, heat tolerance, weatherability, and so much more.

Choosing the correct powder for your application all depends on what is being coated, if the component will be exposed to harsh conditions, where the component will spend most of its time (inside a house/garage, exposed to the elements, in an engine bay, etc.) and what kind of finish is desired for the end result.

Polyester powder is used in over half of all America’s powder coating processes. This is because it has such a huge application range that you can pretty much coat anything and everything with a polyester powder coat.

Under the broad head of polyester powder coats are a number of different varieties to choose from. Polyester TGIC (Triglycidyl isocyanvrate) powders are a rather robust variety that has a wide application field, but its chemical makeup is rather toxic and special precautions like wearing a proper mask must be taken when using this type of powder.

Under the broad head of polyester powder coats are a number of different varieties to choose from. Polyester TGIC (Triglycidyl isocyanvrate) powders are a rather robust variety that has a wide application field, but its chemical makeup is rather toxic and special precautions like wearing a proper mask must be taken when using this type of powder.

Polyester TGIC-free powders are widely used in environmentally-concerned Europe because they don’t have nearly as many harsh chemicals as TGIC powders. Benefits of TGIC-free powders is that they have a longer storage life, so they can be stored in powder form longer than TGIC powders, they have a higher pass efficiency, meaning one coat of TGIC-free powder coating covers better than one coat of TGIC powders, and it provides an exceptionally smooth finish. There is also a shorter cure time needed for TGIC-free powders because they don’t have nearly as much water in them.

Because there is less water in TGIC-free powders, it can present problems, however. While one coat of TGIC-free powder covers well, these coats have to be put on thin in order for them not to crack. Thus more thinner coats are needed to achieve the desired thickness and coverage of the coating.

Another polyester variety is polyester isocyanate, or polyurethane.

With a more stable, low gloss finish, this powder coating type is used mostly with flat or matte finishes. It provides a good chemical resistance, as well as built-in blockers.

Super durable polyester powders are the last but possibly the strongest polyester powder variety. This type of powder coat is used primarily in coastal and southern markets due to its elevated gloss and color retention in harsh conditions. Out of all the polyester options, this one would out-perform all the rest in harsh conditions.

Moving on to non-polyester powder varieties, we have Fluorpolymer powder, which is like the “Cadillac of powders”, epoxy powder, hybrid powder, acrylic powder and silicone powder.

Fluorpolymer powder provides a high chemical resistance, long life, superior weatherability, and enhanced UV stability, making it great for outdoor applications. Epoxy powder has a lower UV stability and can tend to chalk, but possesses a high chemical resistance, high salt resistance, and unique flexibility, which allows it to be used as a base for polyester powders. Hybrid powders are just a poly and epoxy mix, which is used a lot for outdoor furniture.

Acrylic powders are highly used by the automotive industry when it comes to clear powder coating because it is very see-through, very chip resistant and very smooth because it has a GMA (glycidyl methacrylate) ingredient. Silicone powders are most often used for high-heat applications as they can tolerate temperatures between 400 to 1,000 degrees Fahrenheit depending on the percentage of silicone in the powder. Powders that are 100 percent silicone can withstand temperatures up to 1,100 degrees F.

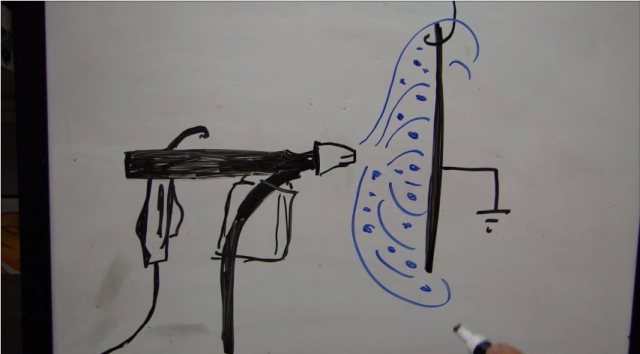

So once your powder has been chosen, what is the mad science behind how it works? Well, using a powder coating gun, powder is given a negative charge (provided with an extra electron) by running over a low or high-voltage metal rod (within the gun).

The component you are coating is attached to a ground, giving the powder a source of attraction. So when the trigger on the powder coating gun is pulled, a cloud of negatively charged powder is dispensed and immediately drawn to the positive charge of the part attached to the ground wire. Once the powder hits the grounded component, it releases its extra electron to the part, causing the powder particles to stick and remain attached to the component.

Of course, there is a dedicated equation for this attraction and sticking process, but we’ll let Pete explain the mathematics to you. What it comes down to is a chemically-driven finish on select components just as unique as the rest of your build.