In the process of building a car, it’s the little things that seem to create the biggest frustrations. It’s slicing your arm on a razor-sharp zip-tie or galling threads on a simple aluminum pipe fitting that can ruin your whole day. We can’t do much to change people’s perceptions on global climate change or the issues in the Middle East, but we might be able to help in making sure you don’t burn up the clutches in your automatic because it was under-filled. It’s the little things that can, and do make a difference. Follow along as we offer a ten-pack of ideas which just might make your life under the hood a touch more pleasant.

1) Getting Grounded

Blacked-out accessory drives are a popular under-hood fashion statement. Did you know that black anodizing also serves as a perfect electrical insulator? We learned this little tidbit from Matt Young at Mechman alternators. We verified it with our digital ohmmeter on a blacked-out Mechman LS-style 170-amp alternator.

Mechman removes the anodizing from the mounting lugs on this alternator but also insists on the use of a dedicated ground cable from the mounting point straight to the battery. Using a dedicated ground cable ensures a solid ground path between the alternator and the battery that prevents damage to the alternator. The two photos above show the only ground path is to the mounting lugs.

2) The Boss

Most modern electric fuel pumps come machined for o-ring boss (ORB) fittings which use an o-ring to seal instead of tapered pipe thread. It’s critical, especially for the inlet side of these pumps (but also for the outlet side), that a tapered fitting be used to prevent cavitation. A squared-off fitting creates a low pressure area that enhances cavitation. While a male AN fitting will screw in – do not use these – as they can creates a restriction that can kill the pump very quickly. As an example, an Aeromotive 15607 is a tapered -8 ORB fitting for a -8 AN inlet to a fuel pump.

3) Take the Short Cut

Try using a hole saw when cutting carpet. We discovered this little tip from the ACC Custom Carpets website. We tried it and it works! If you try to use a drill bit, the bit catches a thread and pulls it right out of the carpet weave. A hole saw cuts the threads much more cleanly without pulling. Try it on an old discarded carpet first, but it worked for us.

4) The Gall!

Aluminum automatic transmission and engine coolers are often powder coated. Meanwhile, the internal threads like the female threads shown above are usually left untreated. Threading in a bare brass or aluminum fitting will likely gall the threads. It also makes removing the fitting nearly impossible without completely destroying the female fitting. Use a liberal coating of Teflon thread paste or pipe-thread tape as a precaution and to create a leak-free connection. Also be sure to apply enough lube so the fitting can be removed easily in the future.

In our case, we added thread tape to two fittings and they tightened up nicely. But of these two fittings, we could only remove one – the other galled even with the tape. So there’s the rub!

5) Save the Thrust-Bearing

This is a simple tip that can save your engine’s thrust-bearing. If your car is equipped with a high-pedal-effort pressure plate. Do the thrust bearing a favor and always start the engine with the transmission in neutral and the clutch released. Depressing the clutch pedal on a high static-load pressure plate puts enormous pressure on the thrust-bearing. It is even worse if the engine has been sitting for a long time and there is no oil on the thrust-bearing. Little things like this can make a big difference.

6) Cut it Clean

We prefer not to bleed all over the car we’re working on. If zip ties are part of your car-building regimen then you are probably familiar with that razor-sharp tail left after trimming the excess tie with a pair of side cutters. If you use a flush-cut pair of side cutters, the tail is removed. Most standard side-cutters will leave a small tail that will slice open bare skin like a razor knife. If you don’t have a pair of flush-cut trimmers, at least spend a second or two and file that sharp edge down – your hands will thank you.

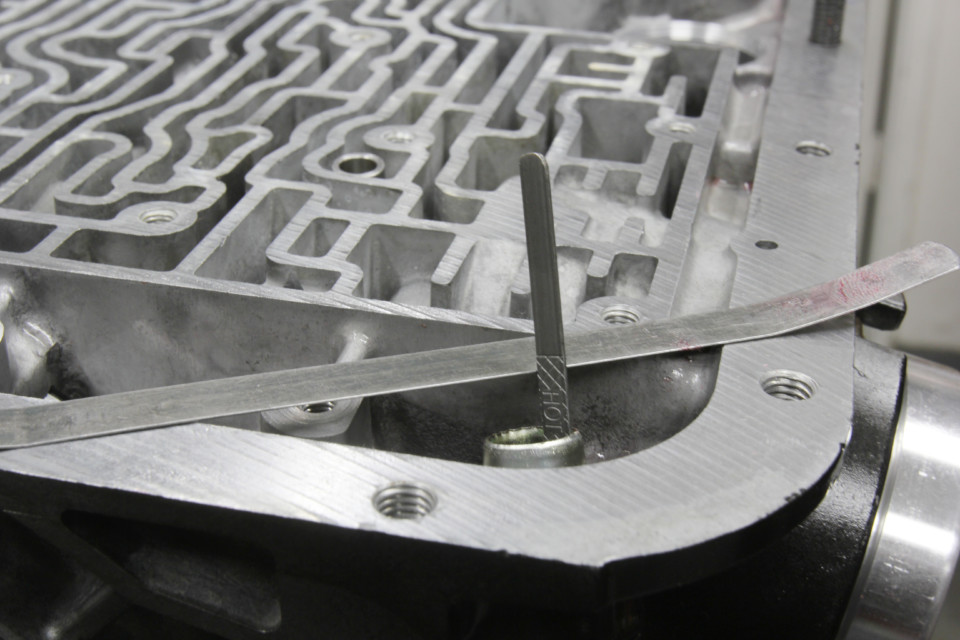

7) Fill Points for Automatics

Performance automatic transmission builders are quick to point out that many transmissions fail because of low fluid levels. The low fluid levels can often be the result of aftermarket dip stick tubes with inaccurate “full” marks. The first step is to verify that your dipstick is accurate.

The “full” level should be at the transmission pan rail with the engine running and lube at operating temp. The reason you always check auto trans fluid with the engine running is, when the engine stops, the converter drains back into the pan and the level increases by more than one quart. Recent testing appears to show that some automatics – especially the 700R4 / 4L60E family – should not run ½-quart below full, but over-filling by a ½ quart is acceptable. Doing so keeps the fluid near the filter inlet under hard acceleration.

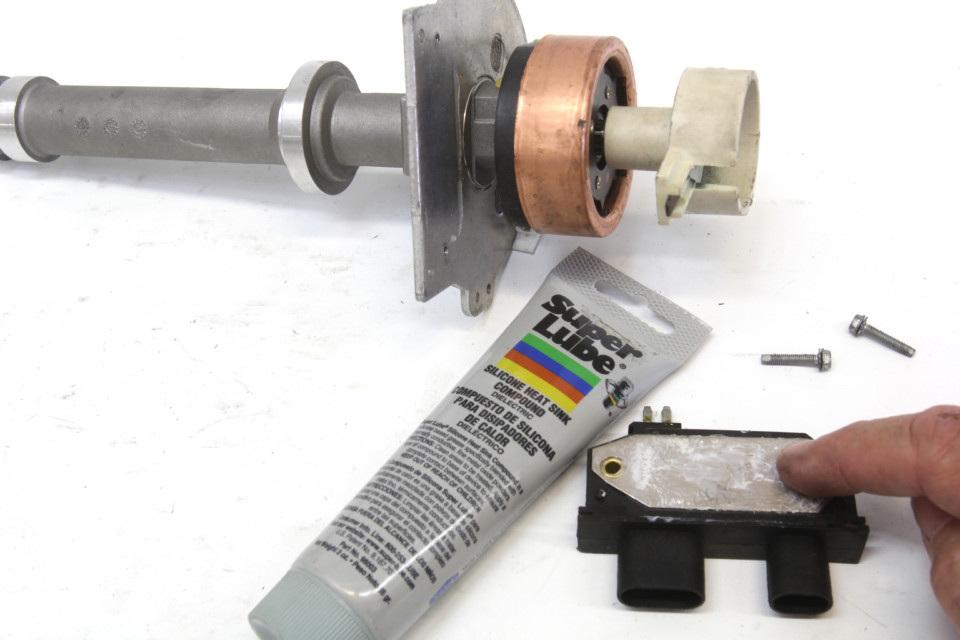

8) Let That Heat Sink In

There are two materials commonly used in performance vehicles – both come in plastic tubes and both are called dielectric, but they perform completely opposite jobs. Dielectric means both materials do not conduct electricity, and therefore are electrical insulators. But, that is where they diverge in terms of how they operate. What’ we’re talking about is knowing the difference between a heat sink material and a thermal-barrier compound. Both materials look similar but perform different jobs.

Let’s take the thermal barrier first. MSD sells what they call Spark Guard – which is a dielectric grease. It is an electrical insulator used to prevent voltage leaks from spark plug boots – among other tasks.

The other compound is a thermal-heat-transfer grease that also comes in a squeeze tube. This material is used to help transfer heat away from items like HEI distributor modules that tend to get very hot (shown). This paste helps transfer heat from the module to the distributor body to prevent overheating the module.

Never use MSD Spark Guard as a heat transfer paste – this would be like wrapping a carburetor with 20-feet of heater hose in an attempt to reduce its running temperature. Always use this thermal transfer paste under HEI modules and save the Spark Guard for insulating spark plug wires.

9) LS Pilot Tip

You’ve probably heard about stuffing grease behind a pressed-in pilot bushing and then driving the bushing out by forcing the grease inward with a large punch or steel dummy shaft tool. The trick works well with most crankshafts. We’ve also seen YouTube video of people stuffing bread into the cavity and pounding out the pilot bushing – which is far less messy.

Do not try this on an LS engine! GM rifle-drills its crankshafts to improve bay-breathing and to reduce weight, placing a freeze plug inboard of the end of the crank to prevent oil leaks. Attempting to use a hydraulic-press method to remove the pilot bushing will only force the freeze plug out of the crank and cause a massive oil leak. Worse yet, the pilot bushing will still be in place! To remove the LS pilot bushing you’ll need an expandable-jaw slide hammer to yank the bushing/bearing.

10) Converter Retention

It’s easy for the converter to slip off one step on the input shaft when swapping transmissions. We found just bolting a long, box-end offset wrench will retain the converter and you don’t have to spend money on (or waste time making) a dedicated converter holder. It’s quick, simple, and keeps the converter where it belongs,

These are 10 tips we have picked up over a lifetime of wrenching. What are some of your favorite tech tips that help you keep your sanity while working on your ride?